Contact Info

Add:No.10-3,Baofeng East Road,XiaoLanTown,ZhongshanCity,Guangdong,China

Phone: +86-760-22284520-2

E-mail: james@chfastener.com

What are the main advantages of precision parts machining?

More and more people tend to choose precision parts and ordinary parts. As a component of machinery, why are precision parts more popular? What are the benefits of achieving precision part machining? Below, our chief engineer will introduce to you:

Nov 21,2024

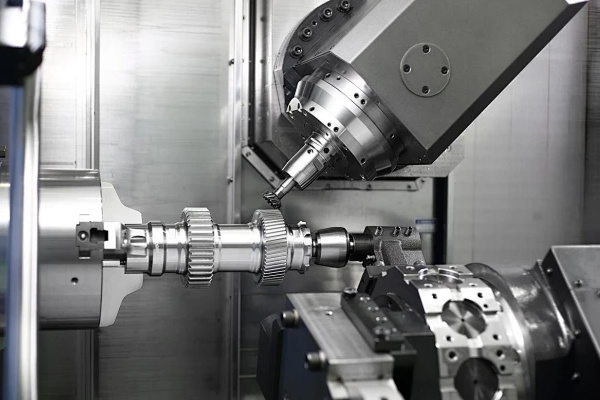

CNC lathe parts processing should pay more attention to these major details!

In fact, a workpiece not only shows the strength of a manufacturer, but also shows its handling methods for some details. For CNC lathe parts, if the manufacturer does not handle them well, then the workpiece is not usable. So, what should the manufacturer pay attention to when processing?

Nov 21,2024

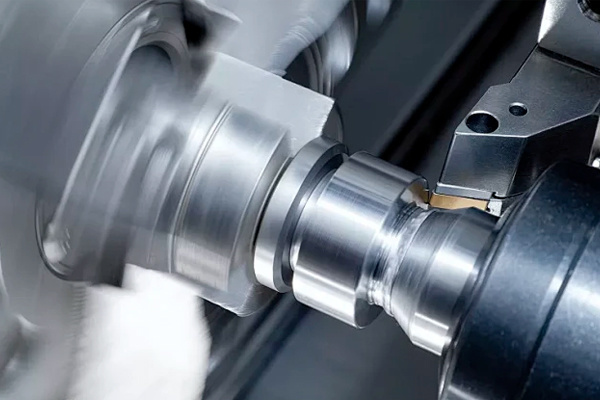

The process of precision parts processing and production

Precision part machining is a complex and rigorous process, which is composed of each step-by-step machining process. So, what are the specific production points of precision part machining? The production process of a machine refers to the entire process of making products from raw materials (or semi-finished products). For machine production, it includes transportation and storage of raw materials, preparation for production, manufacturing of blanks, processing and heat treatment of parts, assembly and debugging of products, painting and packaging, and other contents. The content of the production process is very extensive. Modern enterprises use the principles and methods of systems engineering to organize and guide production, viewing the production process as a production system with inputs and outputs.

Nov 21,2024

Do you know how precision metal parts are processed?

Precision metal parts refer to the collective term for various specifications and shapes of metal blocks, metal rods, metal pipes, etc. manufactured from metal materials. The materials of metal parts include steel and non-ferrous metals (or non-ferrous metals), steel: alloys of iron with a carbon content of 2% to 4.3% are cast iron, and alloys of iron with a carbon content generally ranging from 0.03% to 2% are steel. In Fe-C alloy, various appropriate alloying elements are purposefully added to improve the strength, hardness, wear resistance, and corrosion resistance of steel.

Nov 21,2024

Do you know what precision parts manufacturers need to pay attention to when processing

Precision parts manufacturers attach great importance to the processing and surface treatment of components, therefore, the operation process is also relatively strict. Surface treatment can prolong the life of products and improve quality. Due to the need for polishing treatment on the surface of components, not only can it be affected by the process and polishing equipment, but the polishing itself will also be affected by the material. Therefore, the technology to improve the surface performance of parts needs to be upgraded, but the main ones are hardening film deposition, nitriding, and carburizing technologies.

Nov 21,2024