Contact Info

Add:No.10-3,Baofeng East Road,XiaoLanTown,ZhongshanCity,Guangdong,China

Phone: +86-760-22284520-2

E-mail: james@chfastener.com

What are the factors that affect the surface roughness of cutting in precision parts machining??

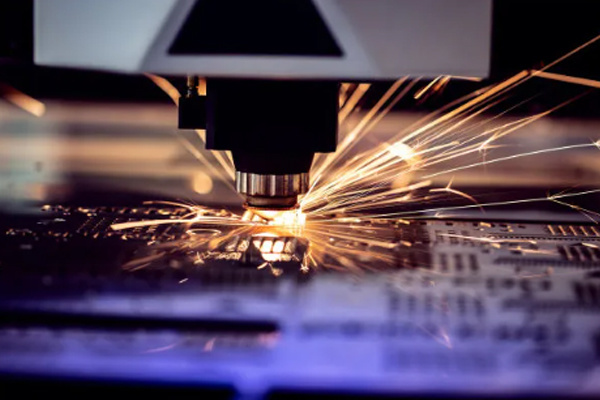

Precision parts manufacturers attach great importance to the processing and surface treatment of components, therefore, the operation process is also relatively strict. Surface treatment can prolong the life of products and improve quality. Due to the need for polishing treatment on the surface of components, not only can it be affected by the process and polishing equipment, but the polishing itself will also be affected by the material. Therefore, the technology to improve the surface performance of parts needs to be upgraded, but the main ones are hardening film deposition, nitriding, and carburizing technologies.

Nov 21,2024

What are the factors that affect the surface roughness of cutting in precision parts machining?

What are the factors that affect the surface roughness of cutting in precision parts machining??

Nov 21,2024

There are many precautions in the process of precision parts machining

There are many precautions in the process of precision parts machining. In mechanics, even small parts have many classifications and great functions. Although parts are small, they have great effects. In modern society, the production of products is inseparable from the use of mechanical equipment. There are many types of mechanical equipment, and usually machines are composed of parts and components, while different types of equipment are composed of different components.

Nov 21,2024

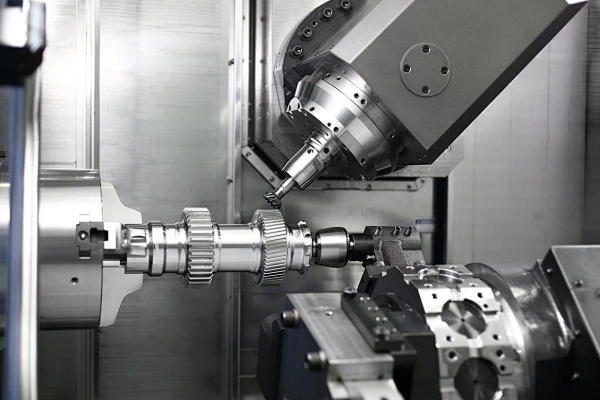

The advantages of precision parts production on CNC lathes

When starting a new plastic injection molding project, the plastic prototype parts ensure that the product design is correct. For most plastic parts, CNC machining prototypes will provide accurate testing requirements. CNC lathe precision parts processing allows you to test the shape, fit, and function of injection molded parts without the need to produce injection mold tools.

Nov 21,2024

What are the benchmark processes for machining precision mechanical parts?

The process benchmark refers to the benchmark used in the process of the part. According to different purposes, process standards can also be divided into process standards, positioning standards, measurement standards, and assembly standards.

Nov 21,2024