News Hotspot

Contact Info

Add:No.10-3,Baofeng East Road,XiaoLanTown,ZhongshanCity,Guangdong,China

Phone: +86-760-22284520-2

E-mail: james@chfastener.com

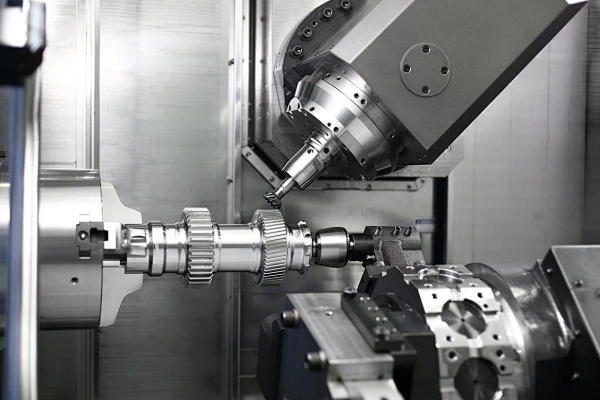

The advantages of precision parts production on CNC lathes

Release Time:

Nov 21,2024

When starting a new plastic injection molding project, the plastic prototype parts ensure that the product design is correct. For most plastic parts, CNC machining prototypes will provide accurate testing requirements. CNC lathe precision parts processing allows you to test the shape, fit, and function of injection molded parts without the need to produce injection mold tools.

The advantages of precision parts production on CNC lathes

1. CNC forming

When starting a new plastic injection molding project, the plastic prototype parts ensure that the product design is correct. For most plastic parts, CNC machining prototypes will provide accurate testing requirements. CNC lathe precision parts processing allows you to test the shape, fit, and function of injection molded parts without the need to produce injection mold tools.

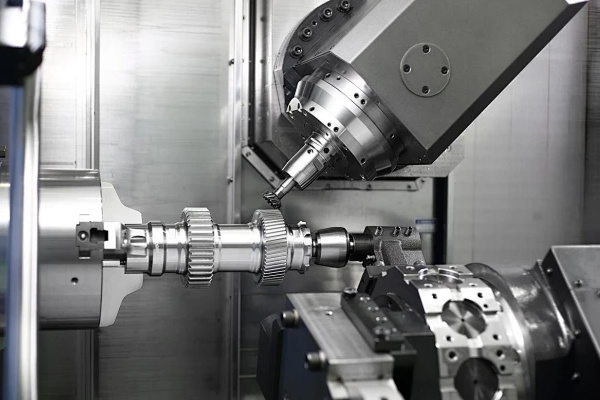

2. Small batch production

Because all you need is a suitable CAD file, precision machining of CNC lathe parts is very good for a small number of parts. Since there are no molds to create, you can save money and time by creating products directly on CNC machines. This makes CNC machining very suitable for machining below 100 pieces (once it exceeds 200 pieces, it becomes cheaper to produce parts using injection molding).

3. Fast turnaround time

Unlike in plastic injection molding, where molds are produced first and CNC machining does not have this requirement. Once your files have been uploaded and approved, production can start immediately. This greatly shortens the production time.

4. High quality parts

CNC lathe precision parts machining has many advantages. This is a more precise process than manual processing, providing precise repeatability. Due to computer control of machine motion, machine tools can move precisely on the axis simultaneously, resulting in complex, three-dimensional shapes that are almost impossible to achieve through manual processing. These qualities make CNC machining a good manufacturing process for jobs that require high precision or repeatability.

We usually control all tolerances within ± 0.2 mm to 0.3 mm. If strict tolerances are important in your critical area, you can specify that we hold tolerances that exceed 0.01 inches.

For plastic components, CNC machining can produce more robust components than 3D printing due to the available materials and production process itself. Therefore, they can withstand the same conditions as injection molded parts.

Key words: