News Hotspot

Contact Info

Add:No.10-3,Baofeng East Road,XiaoLanTown,ZhongshanCity,Guangdong,China

Phone: +86-760-22284520-2

E-mail: james@chfastener.com

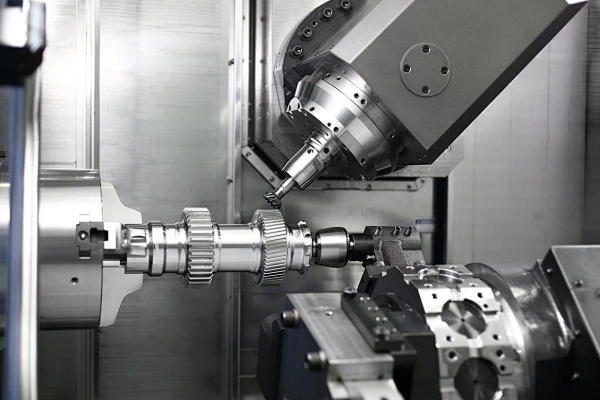

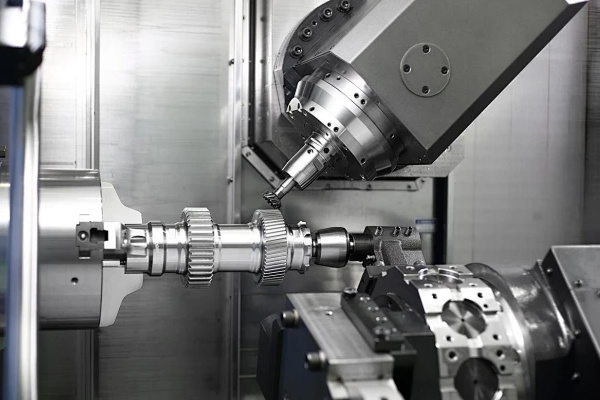

What are the benchmark processes for machining precision mechanical parts?

Release Time:

Nov 21,2024

The process benchmark refers to the benchmark used in the process of the part. According to different purposes, process standards can also be divided into process standards, positioning standards, measurement standards, and assembly standards.

What are the benchmark processes for machining precision mechanical parts?

(1) Process benchmark

The process benchmark refers to the benchmark used in the process of the part. According to different purposes, process standards can also be divided into process standards, positioning standards, measurement standards, and assembly standards.

1. Process benchmark

In the process diagram, the reference used to determine the size, shape, and position of the processed surface of this process is called the process reference.

2. Positioning reference

The reference used to determine the correct position of the workpiece on the machine tool or fixture during processing is called the positioning reference.

3. Measurement benchmark

The reference used to measure the shape, position, and dimensional errors of workpieces during or after processing is called the measurement reference.

4. Assembly reference

The reference used to determine the relative position of parts or components on the product during assembly is called the assembly reference. The inner hole of a gear is the assembly reference for that gear. In general, the design benchmark is given on the part drawing, and the process benchmark is determined by the process personnel based on the specific process selection.

When analyzing benchmark issues, pay attention to the following two points:

1) The points, lines, and surfaces that serve as benchmarks may not necessarily exist specifically on the workpiece (such as hole centerlines, axis lines, etc.), but are reflected by certain specific surfaces, which are called base surfaces. For example, the centerline of the inner hole is reflected through the surface of the inner hole, with the centerline of the inner hole as the reference and the surface of the inner hole as the base. Therefore, the problem of selecting a benchmark is the problem of selecting the appropriate base plane. Specifically, sometimes for the sake of narrative convenience, benchmarks and bases can be collectively referred to as benchmarks.

2) As a benchmark, it can be points and lines without an area or very small surfaces, but the base surface representing this benchmark always has a certain area. For example, installing a long axis on a lathe, with the reference line being the axis, does not have an area; The base surface is a conical surface, which has a small area but does have a certain area.

Key words: